| EN |

|

X

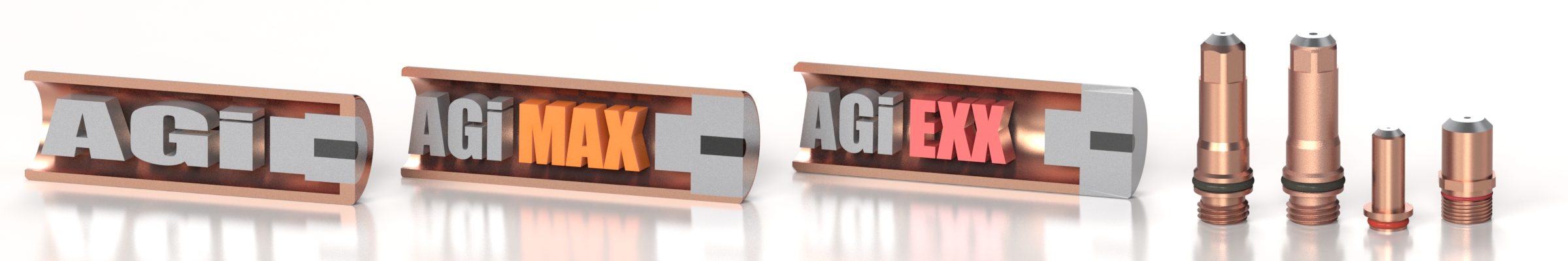

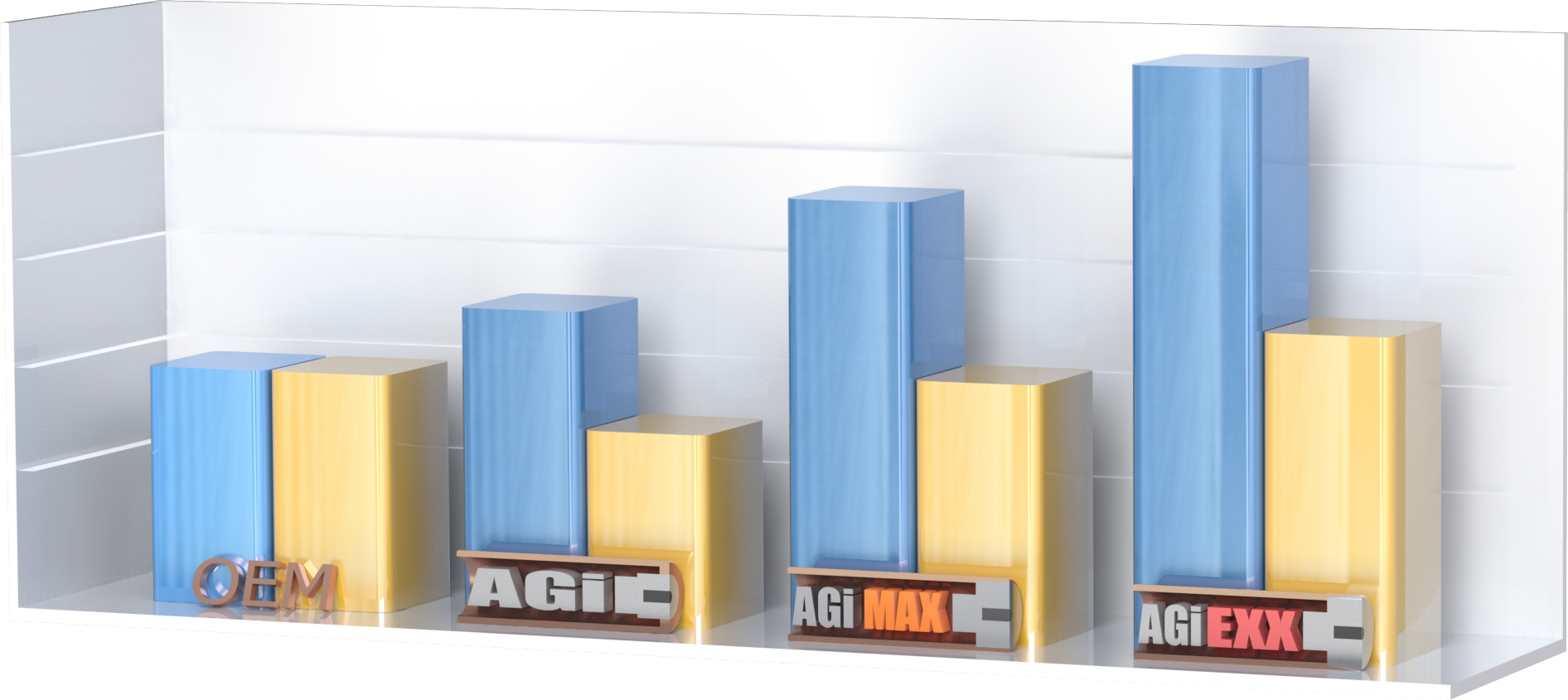

| > GOOD | > BETTER | > the BEST |

|

|

|

|

Standart AGi electrode

Normal Ag insert for standart cutting operations

|

Improved mid. range AGi electrode

"Silver top" electrodes

|

No compromises AGi electrode

"Silver head" electrodes for heavy duty cutting operations

|

|

|

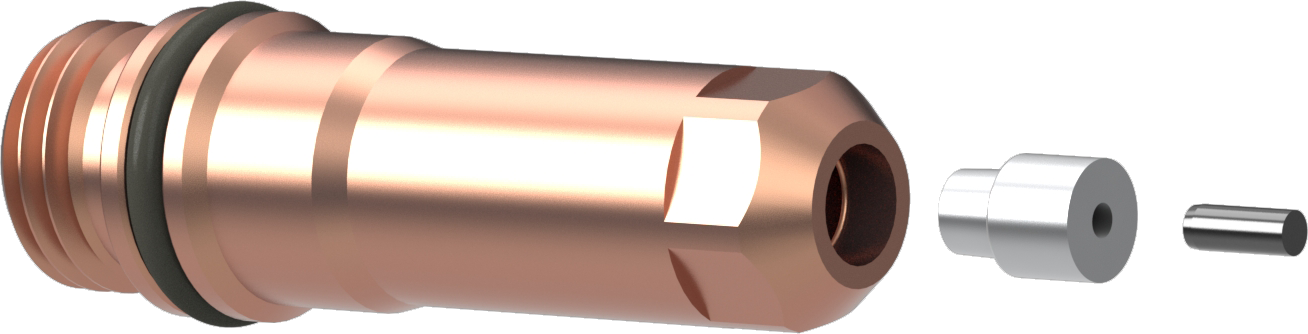

ADJUST ARC VOLTAGE In order to maintain the proper torch-to-plate distance in systems using a voltage-based height control, arc voltage should be increased in 5-volt increments throughout the life of the AGi electrodes. The first adjustment is usually needed at the time that you would replace a copper electrode. To maximize consumable life, continue to adjust arc voltage to maintain the initial torch-to-plate distance. |

| » AJAN® |

| » CEBORA® |

| » DAIHEN® |

| » ESAB® |

| » HYPERTHERM® |

| » THERMAL DYNAMIC® |

| and other plazma cutting sources types... |